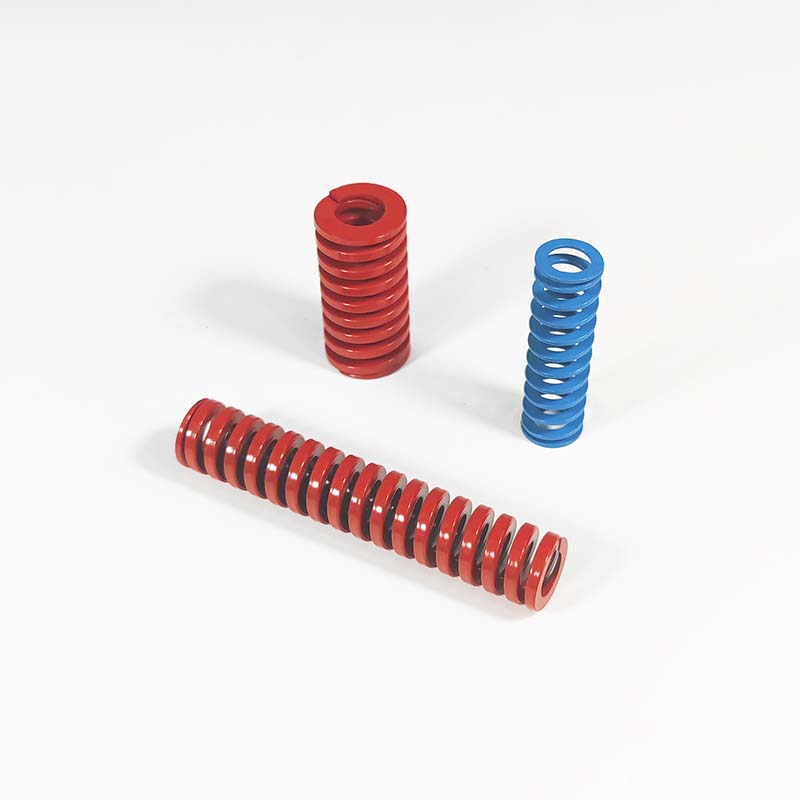

Factory Custom spiral shock Suspension compression spring

Basic Information

compression springs are widely used in independent suspensions, especially in independent suspension of the front wheels. However, in the non-independent rear suspension of some cars, coil springs are also used for their elastic elements. Compared with the coil spring and the leaf spring, it has the following advantages: no lubrication, no sludge, it does not require much longitudinal installation space; The spring itself has a small mass.

Specifications

| Product Name | Custom Automotive Car Suspension Coil Compression Spring |

| Materials | Alloy Steel |

| Application | Automobile/Stamping /Home Appliance ,Industrial, Auto/Motorcycle, Furniture, Electronics/Electric Power,Machinery Equipment,etc. |

| Payment Term | T/T,L/C,Western Unoin,etc. |

| Packing | Inner packing-plastic bags;Outer packing-Cartons,Plastic pallets with stretch film |

| Delivery Time | In stock:1-3days after received payment ;if not,7-20days to produce |

| Shipment Methods | By sea/Air/UPS/TNT/FedEx/DHL,etc. |

| Customized | Support ODM/OEM.Pls provide your springs drawings or detail specification,we will customize springs according to your requests |

Why Choose Us

From the perspective of energy, springs belong to "energy storage elements". It is different from shock absorbers, which belong to "energy-absorbing elements", which can absorb some of the vibration energy, thereby attenuating the vibration energy transmitted to people. And the spring, which deforms when vibrating, just stores the energy, and eventually it will still be released.

DVTcapabilities are not limited to manufacturing. Our production and engineering experts will work with your team to design and produce the components you need using all of the tools at our disposal, including state-of-the-art software, specialized equipment, and a team of subject matter experts. We even offer prototyping and tooling assistance according to customer’s requirements. No matter where you are in the design or production process, we have the knowledge, experience, and tools to bring your project to life.