Products

-

Mechanical Springs

Mechanical Springs

Discover the Unseen Backbone of Everyday Objects and Machinery!

Springs, those unsung heroes, silently provide essential support to numerous applications in various industries. Applied in the automotive sector, mechanical applications, home appliances, and medical devices—these vital components are often concealed, but their significance cannot be overlooked!

Steel, the Key to Elastic Performance:

The production of mechanical spring wire relies on the remarkable properties of steel wire. This versatile material possesses the unique ability to return to its original shape after being bent, compressed, or extended. This elasticity is crucial for applications requiring repetitive motion and force absorption.

The Process Behind the Spring Wires:

The manufacturing process of mechanical spring wire begins with wire rods featuring medium-to-high carbon content. These wires undergo meticulous preparation involving batch acid pickling, phosphate treatment, and neutralization. The initial steps of dry drawing employ calcium-based lubricants, followed by sodium lubricants in the final stages.

Premium Options for Special Applications:

In specific cases requiring stronger materials, stainless steel wires are employed, resulting in a production process that substantially differs from the one previously described.

Ensuring Quality and Reliability:

Depending on the intended application, multiple tests are conducted to guarantee the quality of the wire. These tests include tensile tests, torsion tests, bending tests, and surface defect inspections.

Trust in DVT Springs Vendor:

With our expertise in steel wire applications, DVT Springs Vendor offer top-tier solutions, including different surface plating and powder coating and precoating products.

Contact Our Team:

For more information or assistance, please do not hesitate to reach out to our engineer sales director at sherry@dvtspring.com. We are here to serve you and meet your needs in the different springs including mechanical spring wire production. -

Custom Different diameters Compression spring with base

We have more than 16 years of spring manufacturing experience, if you need to feel free to contact us!

-

Factory custom alloy small spiral torsion spring

We have more than 16 years of spring manufacturing experience, if you need to feel free to contact us!

-

Helical Spiral Heat Resistant Stainless Steel metal Coil Spring Compression

Customize the compression spring of different wire diameters, if you need to contact us at any time!

-

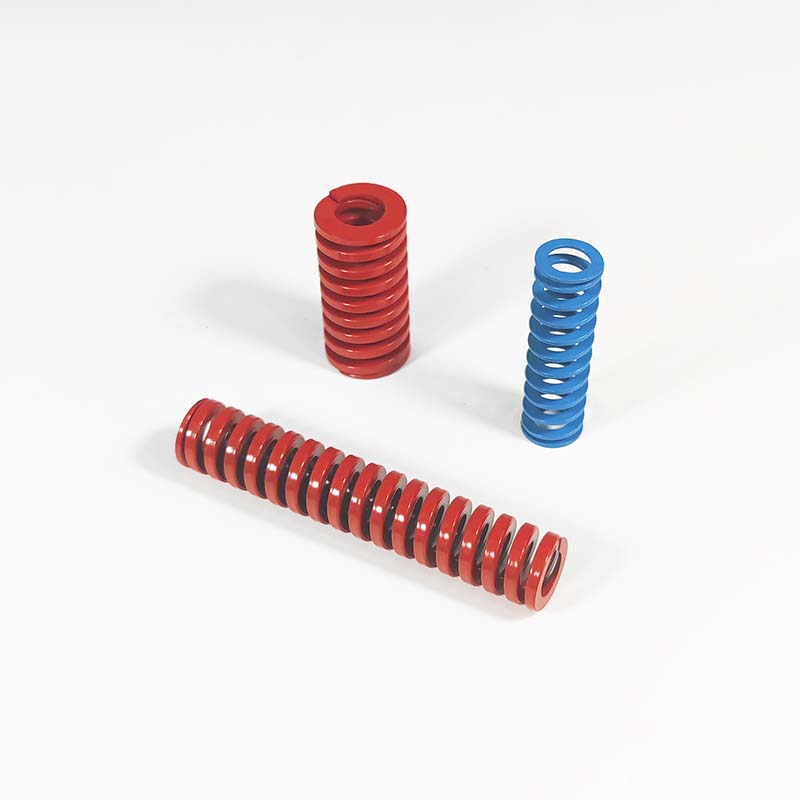

Customized mould spring compression mold spring die springs suppliers

The mold spring is an auxiliary device for the mold. Its main function is to generate elastic force to help maintain a certain pressure on the contact surface between the mold and the workpiece, so as to ensure the shape and dimensional accuracy of the workpiece.

-

Custom high quality Carbon steel 304 316 stainless steel double hook torsion spring

This spring is a type of water tank baffle spring, located on the baffle valve of the toilet water tank. Its purpose is to help the baffle close tightly and prevent water leakage from the water tank.

-

Factory Custom spiral shock Suspension compression spring

- Durable powder coat finish

- Restore height and improve handling.

- High quality springs for increased loads.

- Springs are made from high-strength Steel, shot-peened, Heat Treated.

- Suspension coil springs are used primarily in Motorsports, Street Performance and Off-Road & Powersports markets.

-

Oval compression springs for precision instruments

Oval compression spring for electronic instruments has the advantages of long life and low price

-

304 stainless steel small compression spring for Valve spring

This compression spring applied in the solenoid valve, long service life, excellent spring performance, the company can customize the full type of compression spring, looking forward to your inquiry!

-

-

Custom industrial die compression springs

A die spring is a spring used in a die or fixture to help maintain the clamping force of the die or fixture and maintain its exact position.

-

Heavy duty alloy die compression spring

A die spring is a spring used in a die or fixture to help maintain the clamping force of the die or fixture and maintain its exact position.