Wholesale Garage door hardware manufacturer Torsion spring/Chinese garage door spring

Basic Information

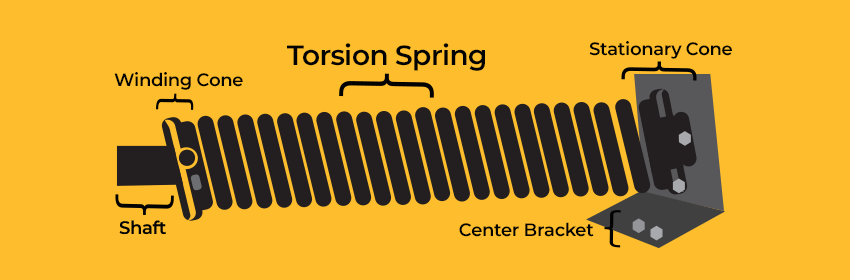

The garage door manufacturing industry relies on torsion springs for complete and functioning garage door systems. In most cases, there is at least one torsion spring in every garage door system, across multiple garage door styles. Whatever type of garage door system you produce and repair, chances are you’ll need torsion springs to make it work. Here are some garage door styles that require torsion springs for proper functioning:

- High-lift and vertical-lift doors

- Roll-out garage doors on tracks

- Heavy-duty overhead doors at industrial loading docks

- Hinged garage doors

- Most other styles of residential and commercial automatic and manual garage doors

Without torsion springs, garage doors would be difficult to operate. Automatic openers would need much more power to lift and close such heavy doors. Torsion springs offset this weight to make it much more manageable. This makes it easy to open and close a garage door manually, and it allows the garage door opener to use less energy to operate the door. Torsion springs make the garage door experience more convenient than it could ever be without them.

Specifications

| OEM/ODM | available |

| Main Products | compression spring, tension spring, torsion spring, wire forming, etc. |

| Specification | wire diameter from 0.1mm to 40mm |

| Material | carbon steel (SWC), stainless steel (SUS), music wire (SWP), alloy steel, SEA9260/9254/6150, SUP9/SUP10/SUP12, 51CrV4, inconel X750, etc. |

| Surface Treatment | zinc plated, electrophoresis, oxidation black, powder coating, blasting, geomet, rust-preventative oil, nickel plated, etc. |

| Packaging | inner plastic bag, outer standard carton box.Or at your request. |

| Certificate | ISO/TS16949-2002, ISO9001-2000, ISO14000 |

| Lead Time | samples:3-7 days; batch goods: 7-15 days after deposit recieved. |

| Payment Term | T/T, L/C, western union, paypal, etc. |

| Shipment | by sea, by air, UPS, TNT, Fedex, express delivery, etc. |